Wearables at Designworks

We’re looking forward to the SEHTA conference this Friday, including seeing what new developments are on offer amongst wearable devices.

It’s gratifying to see that as the physical size of technologies comes down year after year, healthcare interventions can increasingly be offered to better accommodate user’s lifestyles and maximise their wellbeing.

We had a look back at developments with wearables of all different types that we’ve been able to contribute to in the past.

Atlantic Therapeutics provide professional and consumer medical devices to assist improving bladder control. We’ve worked closely with them to develop new hardware and garments for their Innovo product line, which provides electrical stimulation to targeted muscle groups. Their legacy device involved straps and adhesive gel electrodes to provide muscle stimulation, but it required time and good technique to position correctly. The technology in the new Innovo product uses electrodes and circuits which are produced using a novel conductive ink printed directly on the garment. The predictable fit of a garment means the system can now reliably direct the stimulation to the correct muscle group on the body.

A bespoke sizing strategy of nine SKUs was delivered using AlvaForms to test and verify the fit and conformity for the garment’s design versions. Despite this inclusive sizing, embedding the circuit into the garment panels meant it would be subject to more stretching and stresses as it was taken on and off. To validate durability and performance of the product, a rig was developed and built to simulate the ‘wear’ of repetitive stretch cycles whilst the resistance of the conductive pathways were monitored.

Connectivity for Innovo is provided by a small smooth connector plug that clips onto the shorts for discretion beneath clothing. The corresponding connector socket on the shorts is mechanically fixed and bonded to the garment such that it doesn’t dislodge with movement and moisture, resulting in shorts that are machine washable whilst still meeting the stringent needs and requirements for a medical device.

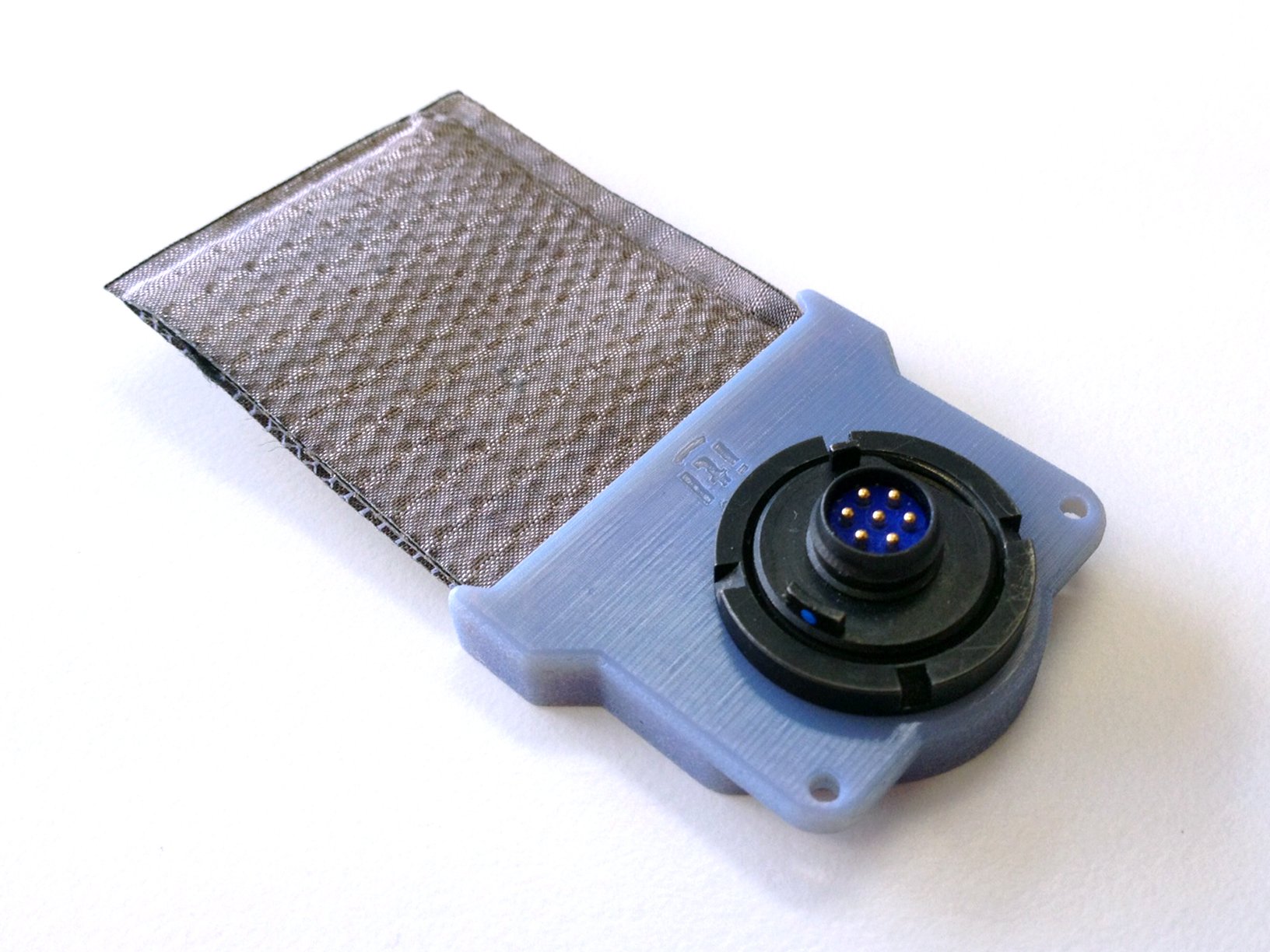

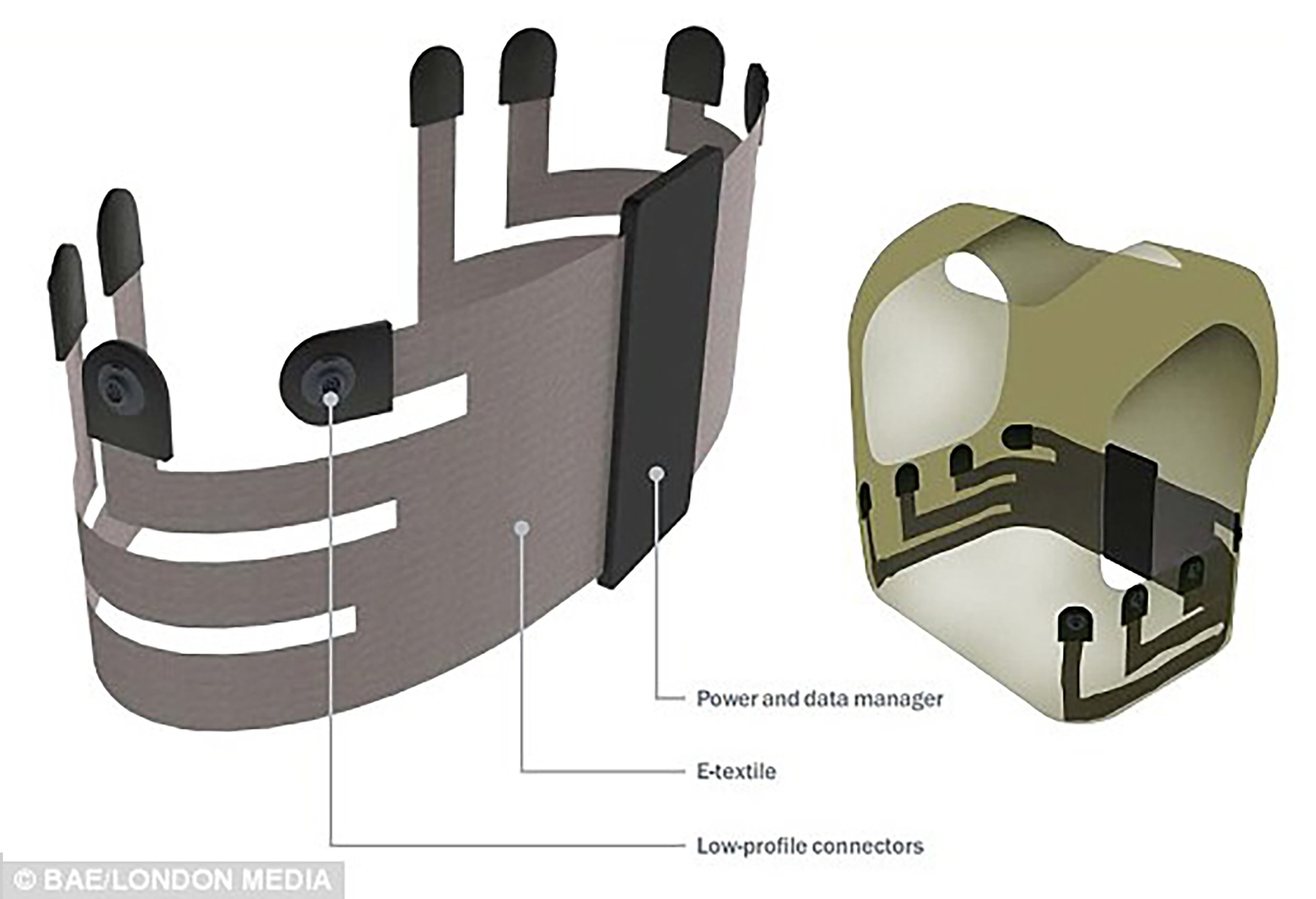

When developing this part of the system, our engineers called upon their experience with Molliflex designing connectors for their military intelligent textiles.

Intended for use on the exterior of a military vest, the testing procedure for the Molliflex connector required a single-handed insertion with a gloved hand after the user had crawled along dragging the garment through mud for a given distance. Accordingly, the contacts would wipe one another clean as the connector was inserted.

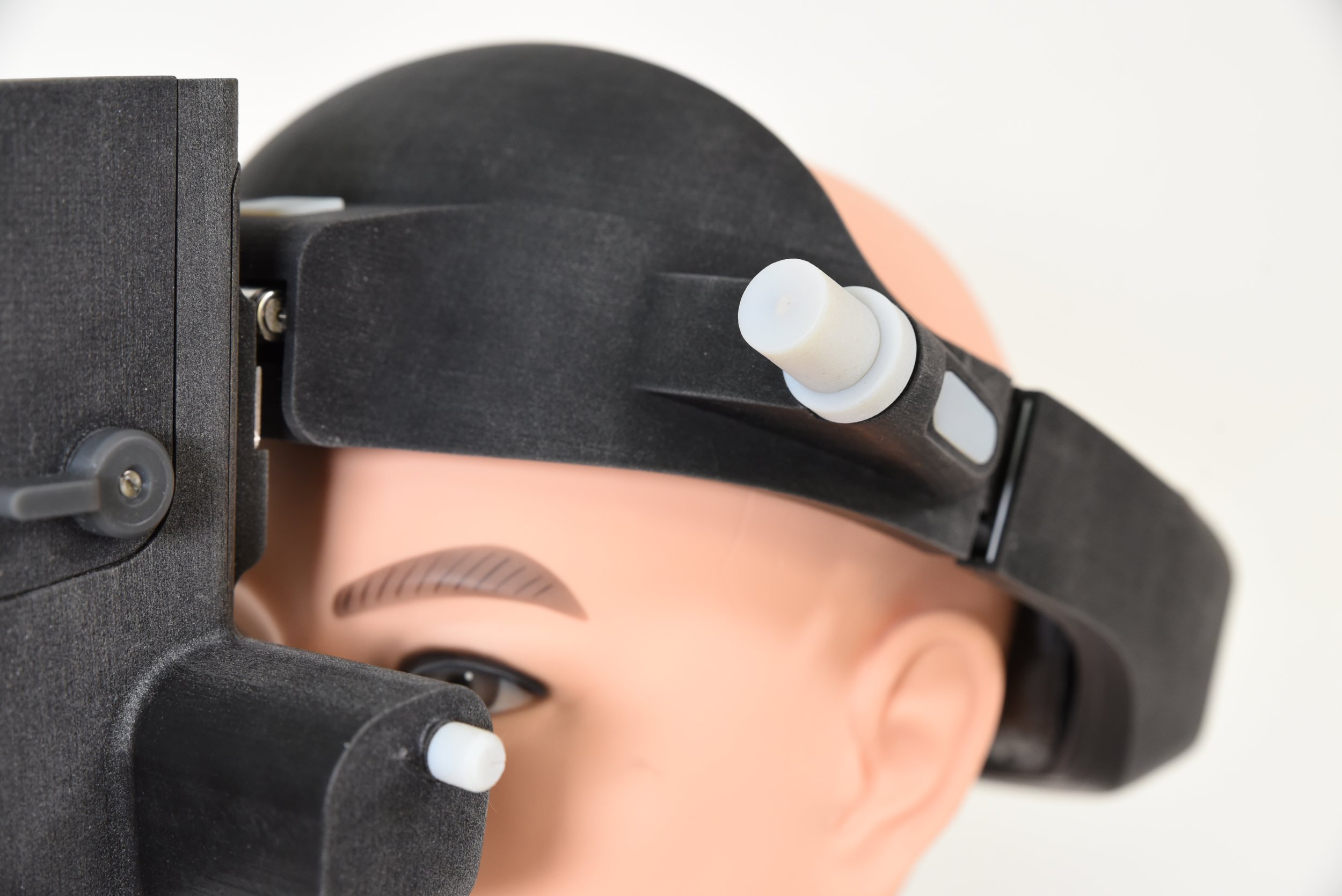

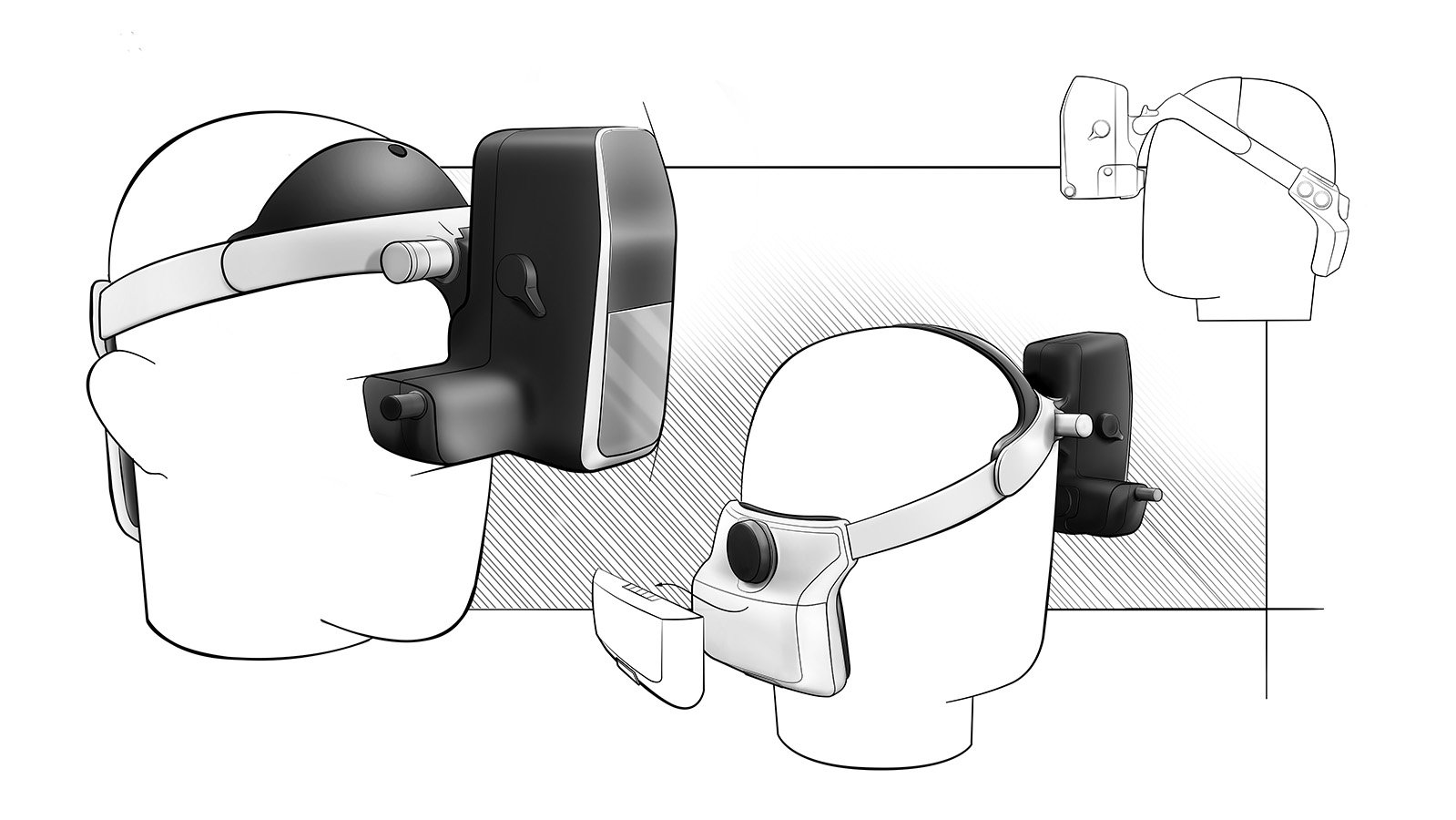

After helping Keeler with their Pulsair Tonometer previously, we were engaged to develop a new digital indirect ophthalmoscope with them. The head-worn device allows clinicians to keep their hands free during examination. The headband format permitted the large technology package of lenses, lamps and a camera to be retained securely, whilst the other necessary components including the lithium battery and processor could help balance them at the rear of the head.

A forehead ‘cup’ was incorporated to rest more of the mass of the device on the top of the head, thereby reducing undue compression from the straps. Development rigs were tested to accommodate being taken on and off repeatedly throughout the day despite various positions of ponytail and headwear such as scarfs and turbans.

Another project with a head-worn wearable was for video games developer Ninja Theory. They wanted to measure players’ biomarkers during gameplay to judge their physical reaction against what they were experiencing inside the Hellblade game as protagonist ‘Senua.’

After consideration of several sites, the temporal artery was selected as a reliable location to read the optical properties of blood vessels without disrupting gameplay. Off-the-shelf optical sensor modules were mounted to custom PBCs at either temple, and post-processing algorithms written to display the information in real time against the game viewport, and a camera view of the player.

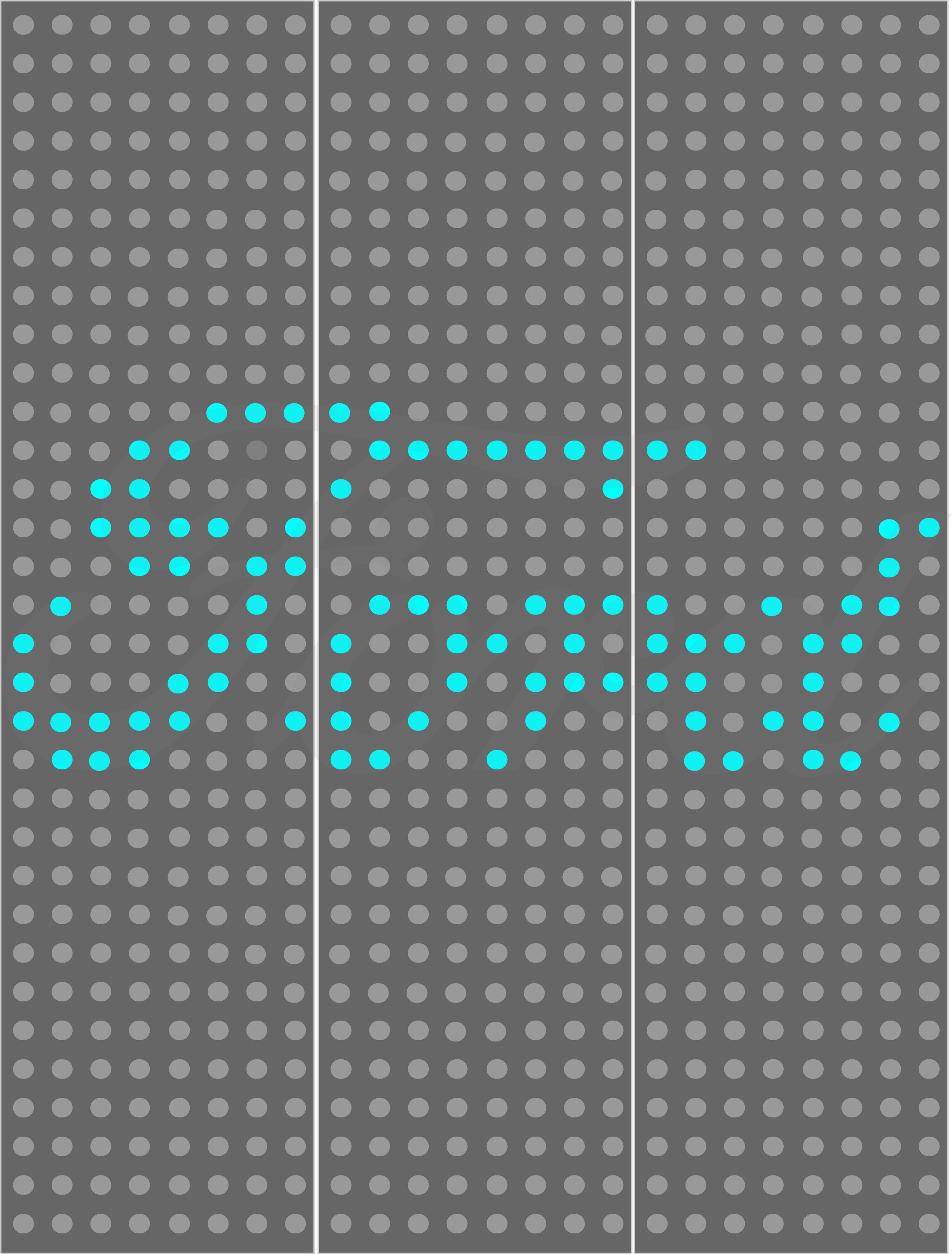

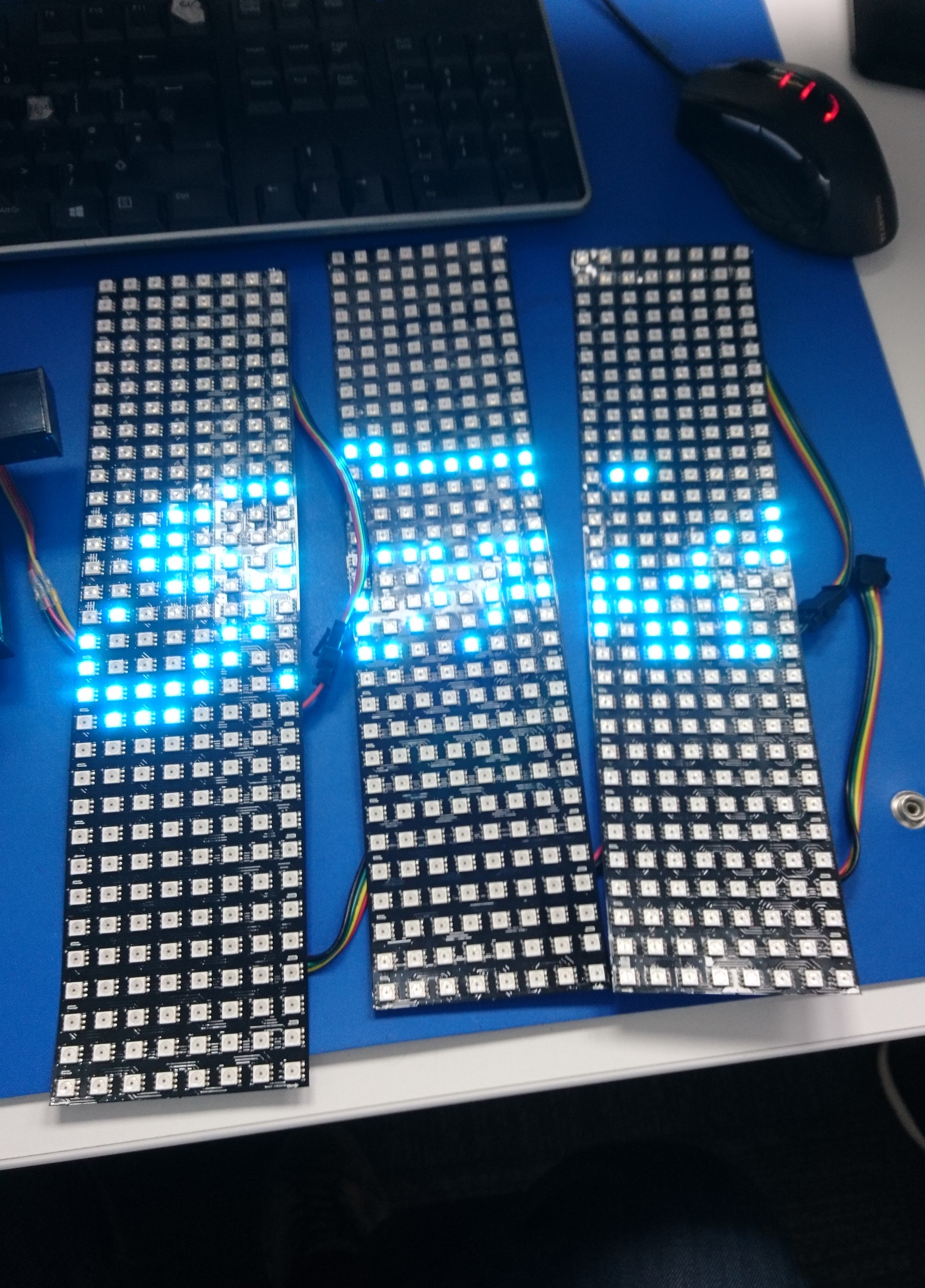

For Ford’s ‘Share the Road’ campaign, Designworks’ electronic engineering team delivered the fun ‘emoji’ cycling jacket. Arrays of LEDs in the rear displayed different graphics (including emojis) that the wearer could trigger wirelessly via a console on the handlebars of the bicycle.

The LED array had to be sufficiently flexible to deform across the rider’s back and bright enough to be seen in daylight, meanwhile the battery and processing that powered and drove it needed somewhere comfortable to stow.

Across medical, military and marketing, there’s been quite a diversity of projects. If you’ve a challenge that you think developing a wearable with us might address, please feel free to get in touch here.